Category:

keyword:

- 产品描述

MULTI WEDGE BELT

-

- Commodity name: MULTI WEDGE BELT

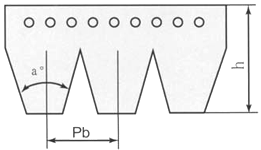

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Mainly used for the transmission of power equipment such as engines and motors, widely used in the automotive parts and electromechanical industries

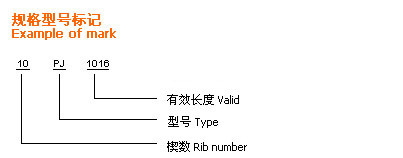

Main models : PH、PJ、PK、PL、PM

In terms of transmission technology research and innovation, the company has successively launched products such as high operating characteristic automotive V-belts, high impact environmentally friendly nano V-belts, cold resistant snow sweeper V-belts, and high-performance low heat motorcycle V-belts, and has 31 national independent technology patentsThe company's products are widely popular, with a market coverage rate of 90% in West Africa

Related Products

Products Inquiry

*Leave your contact information to get a free product quote