CONTACT

Service hotline

M.P:86-13958502699

Tel:86-576-83996799

E-mai:kingtie3886@vip.163.com

Add:No. 3 Badu Road, Chicheng Sub-district, Tianta County, Zhejiang Province, China

Products

Cutting belt is different in design and use from a regular V-belt, as it transmits power through the meshing of teeth and pulleys, while a regular V-belt relies on friction between the belt and pulley grooves. Tooth shaped belts are usually used in situations that require synchronous transmission and high-precision positioning, while ordinary V-belts are more commonly used in general friction transmission

Cutting belt is different in design and use from a regular V-belt, as it transmits power through the meshing of teeth and pulleys, while a regular V-belt relies on friction between the belt and pulley grooves. Tooth shaped belts are usually used in situations that require synchronous transmission and high-precision positioning, while ordinary V-belts are more commonly used in general friction transmission

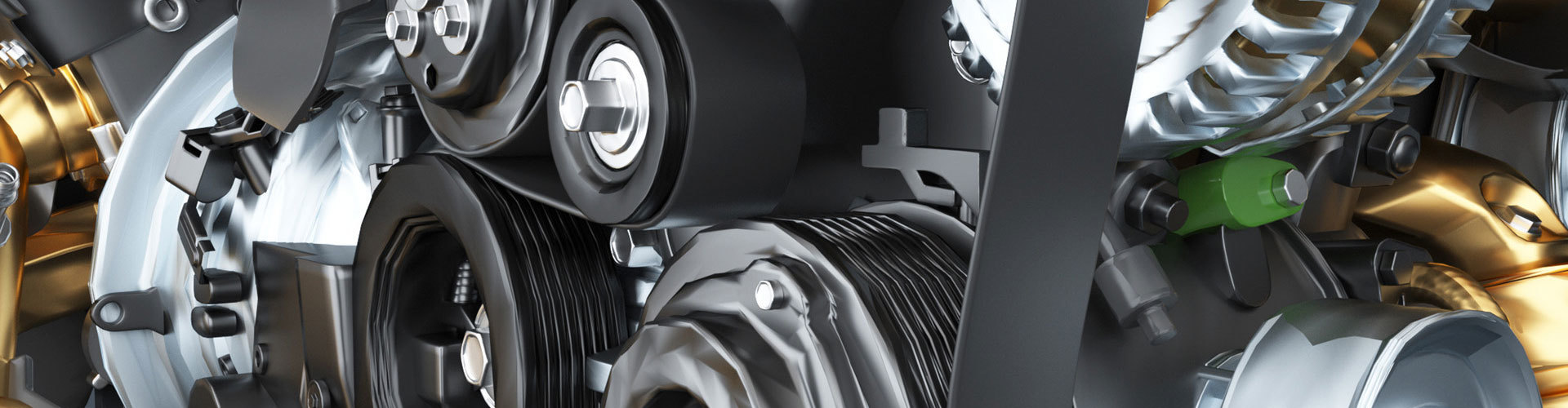

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation

Characteristic: Multi wedge belt transmission has high power, and when the space is the same, it has a 30% higher transmission power than ordinary V-beltsThe structure of the multi ribbed belt transmission system is compact, and under the same transmission power, the space occupied by the transmission device is 25% smaller than that of ordinary V-belts The multi wedge belt has a thin body and is flexible, suitable for transmission with small pulley diameters and also for high-speed transmission, with a belt speed of up to 40m/s; Low vibration, minimal heat generation, and smooth operation